Buy and assign to

multiple learners

Instant access

via email link

Instant certificate

via email

Further Information - Gas Treatment Training

Description

Who is this course for?

This Gas Treatment Training course is suitable for Process and Production personnel

Is previous experience required?

You do not need prior knowledge or experience to complete this course and it is assumed that you are competent in your designated role

How will this course benefit me?

By ensuring you have an overview of industry best practice associated with gas treatment

This course contains seven modules:

Module 1: Introduction to Gas Treatment

Module 2: Problems Associated with Water in Gas Streams

Module 3: Liquid Desiccant Dehydration

Module 4: Solid Desiccant Dehydration

Module 5: Alternative Gas Dehydration Processes

Module 6: Acid Gas Removal Unit

Module 7: Removal of Other Impurities in Raw Gas Streams

How will this course benefit my company?

By ensuring you have an overview of industry best practice associated with gas treatment

What standards are referred to in this course?

This course does not refer to specific legislation or standards.

Is there an assessment?

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

Learning Objectives

• Define gas treatment

• Explain the purpose of gas treatment

• Identify typical gas impurities

• Identify the main gas treatment processes

• Identify the location of treatment facilities in relation to the gas process stream

• Explain how water gets into gas streams

• Explain why natural gas is nearly always ‘saturated’ when it reaches surface facilities

• Explain the purpose of the Inlet separator / filtration system

• Identify the main problems associated with water in gas streams

• Explain how hydrates are formed

• Explain how hydrates can cause process problems

• Explain how corrosion occurs in wet gas streams

• Explain the effects of slugging in pipelines and process vessels

• Explain the effects of water freezing in refrigerated and cryogenic processes

• Explain why gas contracts and piping specifications impose limits on the amount of water in sales gas streams

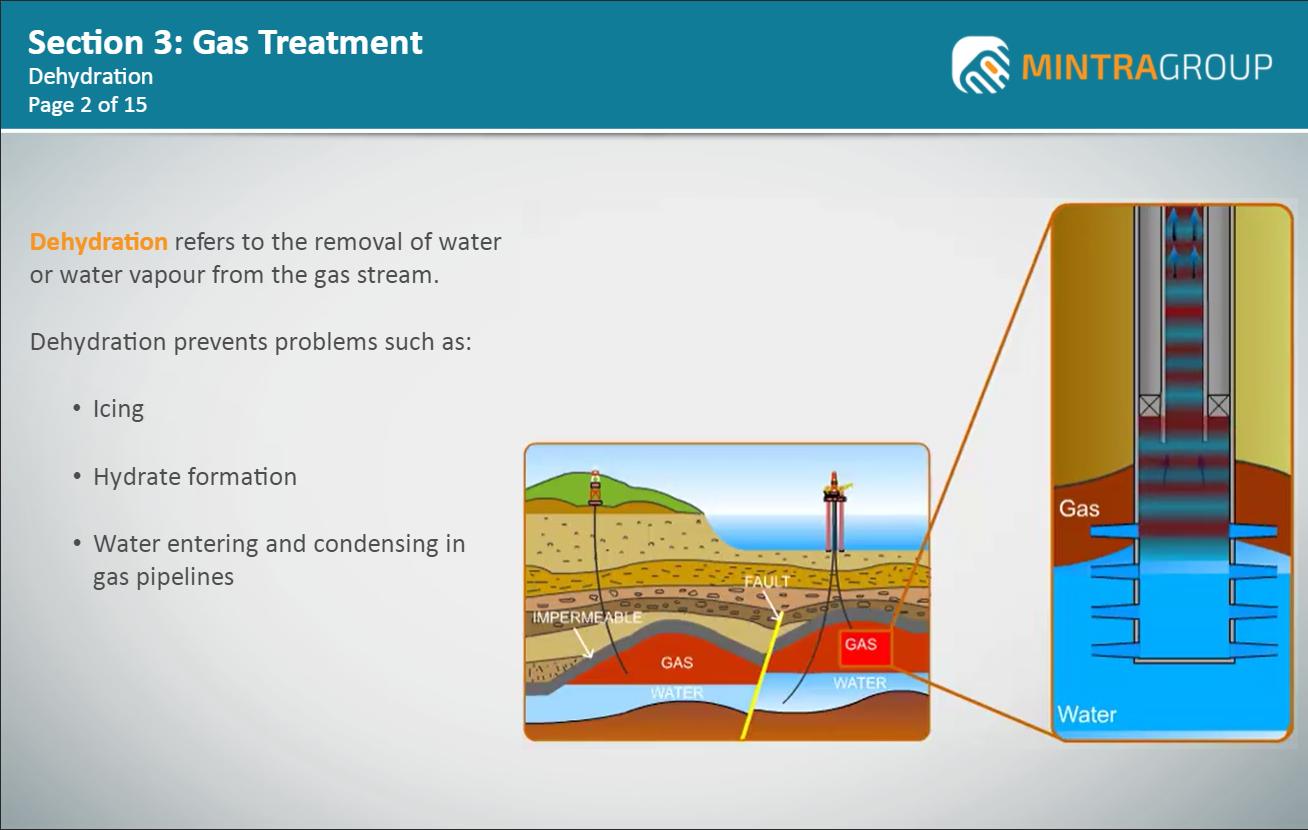

• Define dehydration

• Explain the purpose of dehydrating hydrocarbon-based gas streams

• Define the term ‘dew point depression’

• Explain the importance of dew point depression in gas streams

• Define the term ‘desiccant’

• Identify the main types of liquid desiccant

• List the advantages of using Triethylene glycol (TEG) in gas dehydration

• Explain the principle of the TEG dehydration process

• Describe the TEG dehydration process

• Explain the purpose of the equipment used in the TEG plant

• List the advantages of ‘structured packing’ over trays in glycol contactor towers

• Identify the main operating parameters of a TEG plant

• Explain how the main operating parameters affect the TEG dehydration process

• Explain the relationship between dew point, contact temperature and TEG concentration

• Identify the different solid desiccants used in gas dehydration

• Describe the most commonly used solid desiccant used in gas dehydration

• Explain the difference between absorption and adsorption

• Explain how molecular sieves remove water from the gas stream

• Describe a typical molecular sieve process plant

• Explain the purpose of the molecular sieve process plant equipment

• Explain the molecular sieve dehydration process

• Explain the molecular sieve regeneration process

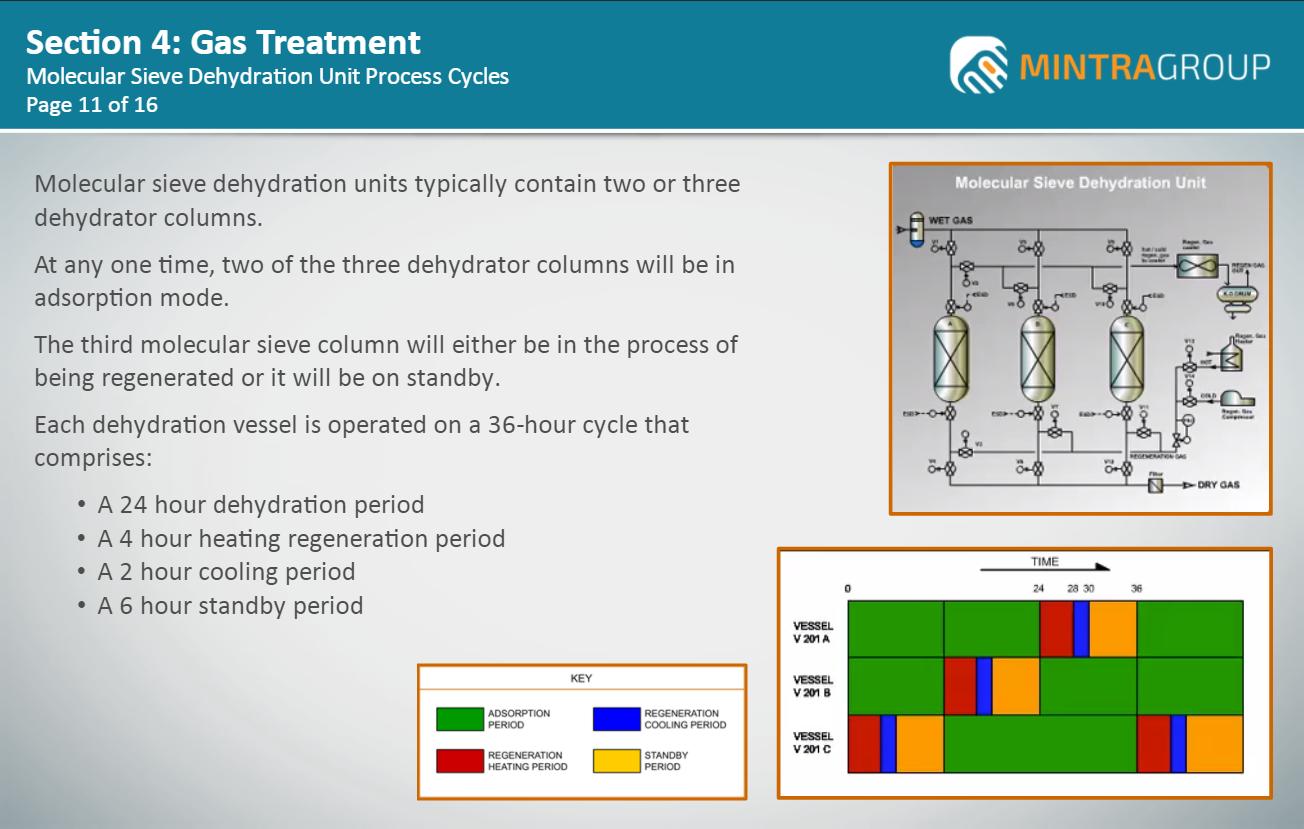

• Explain the various process cycles of a molecular sieve dehydration unit

• Explain the process control of molecular sieve dehydration unit

• Identify typical operating problems of a molecular sieve dehydration unit

• Compare the advantages and disadvantages of liquid and solid desiccant dehydration

• Identify alternative gas dehydration processes

• Explain how filter coalescers remove water from gas streams

• Explain how the Joule-Thompson (JT) effect can be used in gas dehydration

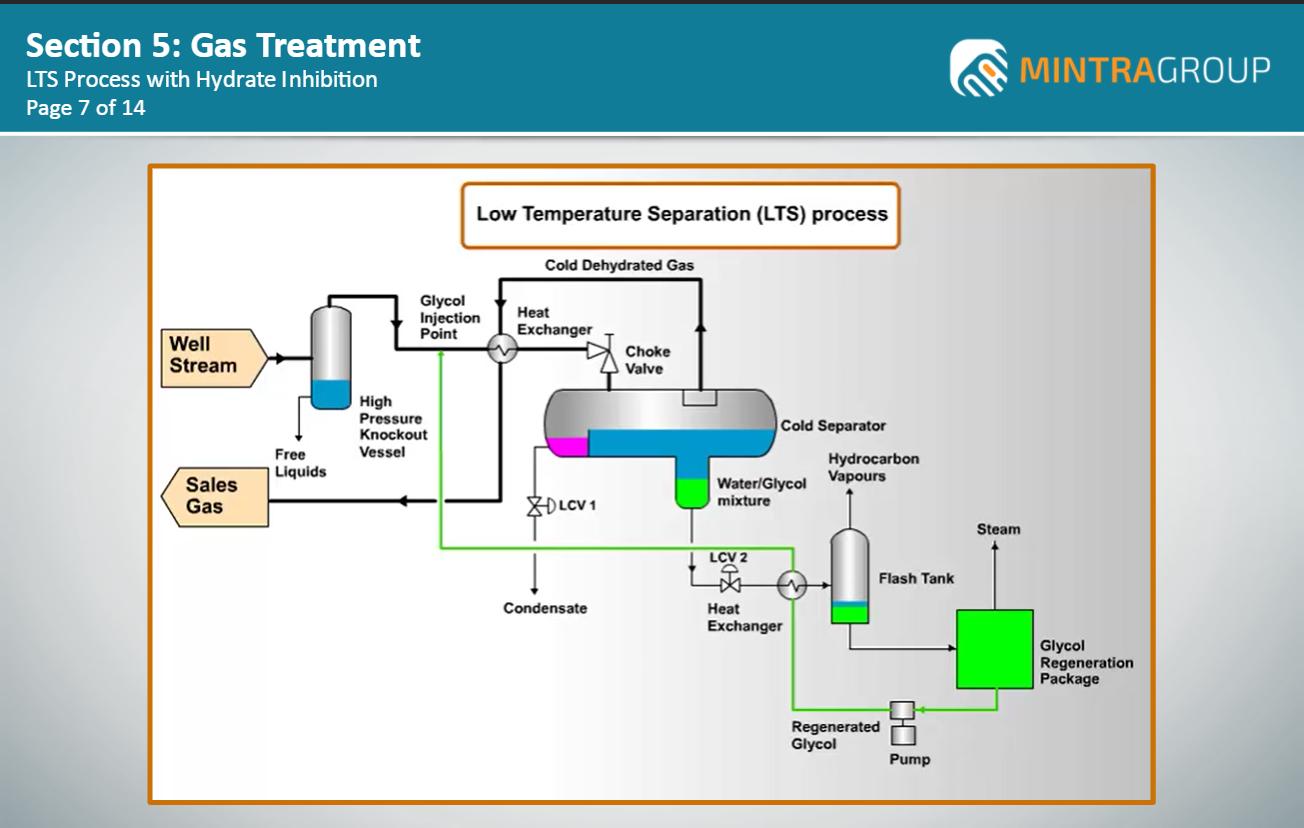

• Explain the Low Temperature Separation (LTS) process

• Explain the Low Temperature Extraction (LTX) process

• Explain the supersonic gas conditioning process

• Describe the IFPEXOLTM process

• Describe membrane separation dehydration

• Define the term ‘acid gas’

• Identify typical acid gases

• Explain the reason for removing acid gases from natural gas

• Identify the main methods of acid gas removal

• Explain the principle of amine-based acid gas removal

• Compare the different amine-based solvents

• Describe a typical amine process

• Explain the purpose of the equipment used in an amine unit

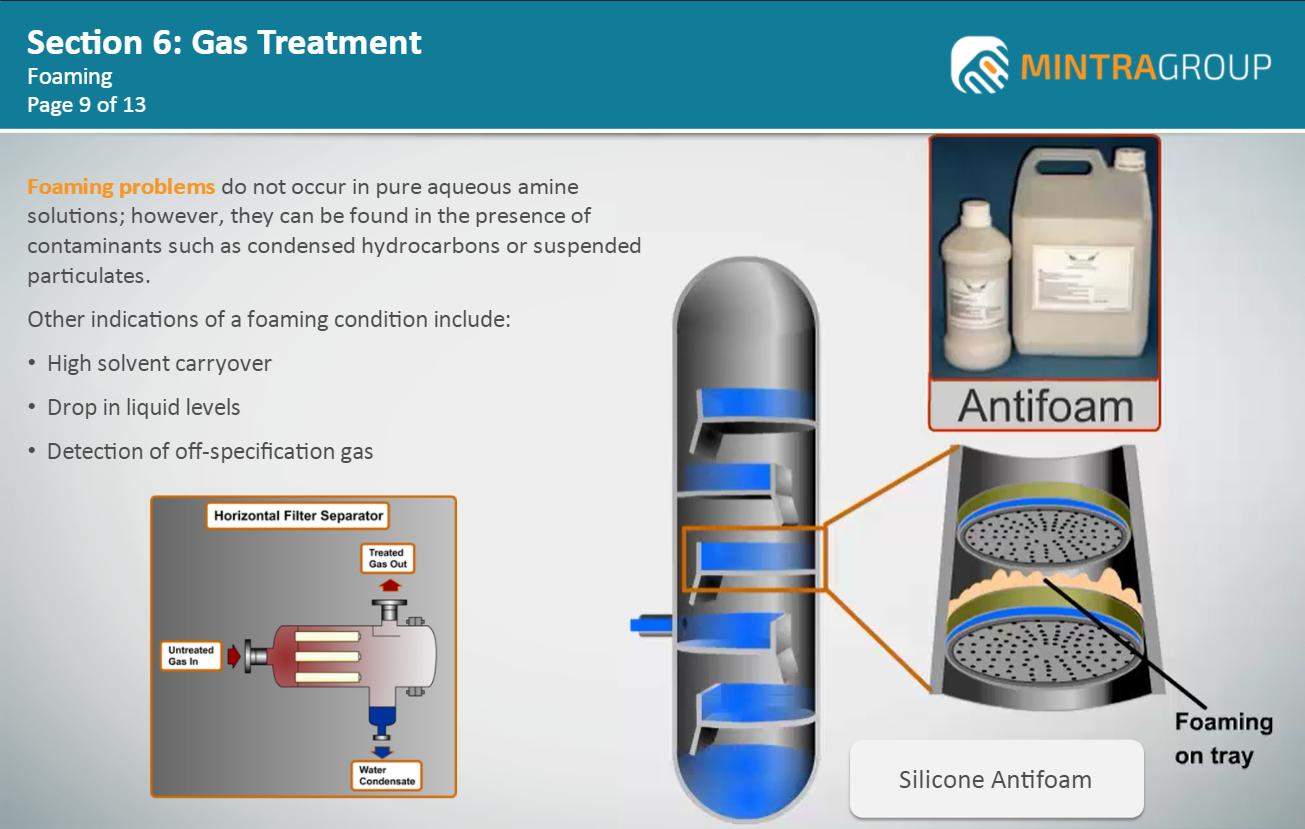

• Describe the main operating problems associated with amine units

• Identify the less common types of impurities found in raw gas streams

• Identify the various methods for removal of the less common types of impurities

• Explain how mercury is removed from a raw gas stream

Assessment

Exam in the e-learning course

System Requirements

• Internet access - users will need a device with a web browser and internet connection

• System - runs on computers, tablets and mobile devices using Windows 7 and above and MAC OS devices running IOS 11 and above

• Browsers - Edge, Chrome, Firefox and Safari

• Minimum browser size – none

• Audio – requires device speaker or headphones

Reviews

Insights & News

At Mintra, we're so much more than just a team—we're a force driving innovation and excellence in maritime training across Europe.

We’re excited to be taking the stage at one of Europe’s leading showcases of organisational learning.

We are delighted to share the exciting news that our People and Culture team has been shortlisted for the prestigious cHeRries Awards!