Mechanical Joint Integrity - Hydraulically Torque and Tension Bolted Connection Techniques (MJI 10,18 & 19) Training - ECITB approved

- COURSE INFO (ME-15)

- Duration

- 141 minutes

- Experience Level

- Intermediate

- Accreditation

- ECITB

- Category

- Engineering & Technology, Process Operations

- Price

- £95.83 exc. local taxes

ECITB accredited

Buy and assign to

multiple learners

Instant access

via email link

Instant certificate

via email

Further Information - Mechanical Joint Integrity - Hydraulically Torque and Tension Bolted Connection Techniques (MJI 10,18 & 19) Training - ECITB approved

Description

The Mintra ECITB-approved online training courses are designed for existing workers to refresh their theoretical knowledge before taking the ECITB Technical Tests.

Who is the course for?

This Mechanical Joint Integrity - Hydraulically Torque and Tension Bolted Connection Techniques (MJI 10,18 & 19) Training - ECITB approved course is aimed at workers requiring refresher training before taking the ECITB technical tests for ECITB standards MJI10: Hand Torque Bolted Connection Techniques, MJI18: Hydraulically Tensioned Bolted Connections, and MJI19: Hydraulically Torque Bolted Connection Techniques.

Is previous experience required?

It is expected that as a participant in this course, you will have received formal training in working with mechanical joints and that you hold suitable qualifications. Completion of this course does not certify you to the ECITB standards but it will prepare you for the technical tests.

How will the course benefit me?

Incorrectly bolted flanges are one of the main causes of hydrocarbon releases, which can have a serious impact on the environment, operating costs and the safety of personnel. This course will give you an understanding of how mechanical joints work and how to use hand and hydraulic torque tightening and bolt tensioning.

The knowledge gained in this course will help you understand how to dismantle, remove and replace components correctly to minimise the leaks and safety concerns associated with incorrectly bolted flanges. It will give an overview of the different types of torque and tensioning equipment and how each should be used.

The course consists of 7 modules;

• Module 1: Introduction to Mechanical Joint Integrity

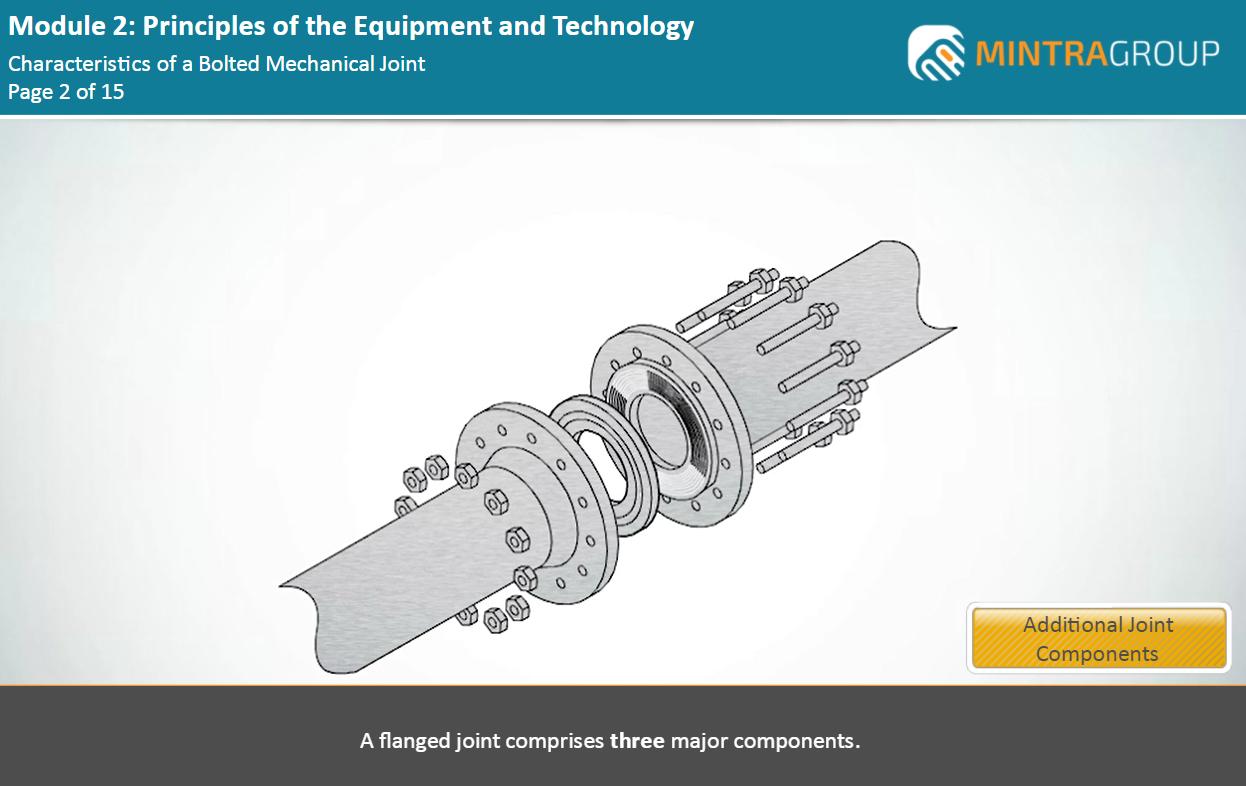

• Module 2: Principles of the Equipment and Technology

• Module 3: Methods of Tightening

• Module 4: Torque Tightening Theory

• Module 5: Dismantling and Removing Components

• Module 6: Replacing Components

• Module 7: Hand Torquin

• Module 8: Hydraulic Torquin

• Hydraulic Tensioning

How will the course benefit my company?

By properly making up bolted joints, you contribute to the integrity of the asset, and the safety of your fellow workers and yourself. A reduction in hydrocarbon releases means a reduced environmental impact and reduced losses of revenue.

What standards are referenced in the course?

This course is written in reference to the ECITB standards MJI10: Hand Torque Bolted Connection Techniques, MJI18: Hydraulically Tensioned Bolted Connections, and MJI19: Hydraulically Torque Bolted Connection Techniques. The course has been approved by ECITB as part of the ECITB/Step Change in Safety MJI model.

Is there an assessment?

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

Learning Objectives

• Describe the specifications covering dismantling, preparation and securing of bolted connections

• Explain how compliance is checked

• Introduce the bolted mechanical joint

• Explain the different kinds of flanges available

• Provide an overview of nuts and bolt technology

• Show the different gasket types

• Describe the correct installation of gaskets

• Describe uncontrolled tightening

• Describe partially controlled tightening

• Describe fully controlled tightening

• Describe the various measuring tools available for controlled tightening

• Show the effects of too low stresses being used

• Show the effects of too high stresses being used

• Explain how torque is calculated

• Explain that the amount of torque put in is not always transferred to the bolt

• Describe how to reduce friction

• Recognise level and extent of responsibility when dismantling bolted connections

• Specify the type of assets to be dismantled and the methods

• Identify isolations and disconnections that may be required

• Describe methods and techniques required for dismantling

• Identify typical problems and how to resolve them

• Recognise level and extent of responsibility when replacing bolted connections

• Describe the types of equipment that might be worked on

• Describe a range of components that may be replaced

• Confirm that replacement parts are suitable

• Describe methods and techniques required for re-assembly

• Identify typical problems and how to resolve them

• Explain the operation of typical hand torque equipment

• Give an example of hand torque tightening

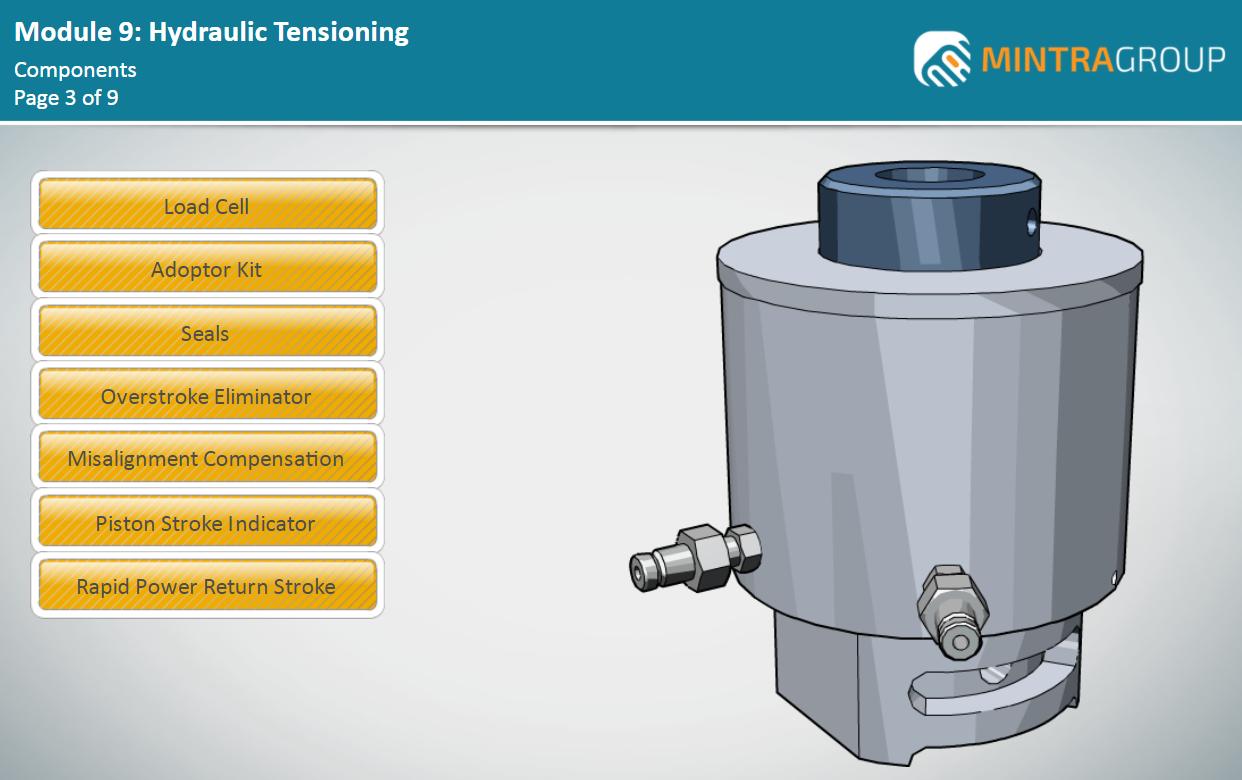

• Describe the components of typical hydraulic torquing

• Explain the operation of typical hydraulic torquing

• Give an example of hydraulic torquing

• Describe the components of a typical bolt tensioner

• Explain the operation of a typical bolt tensioner

• Explain load loss when tensioning a bolt

• Give an example of bolt tensioning

Assessment

End of course exam with an 80% pass mark.

System Requirements

- Internet access - users will need a device with a web browser and internet connection

- System - runs on computers, tablets and mobile devices using Windows 7 and above and MAC OS devices running IOS 11 and above

- Browsers - Edge, Chrome, Firefox and Safari

- Minimum browser size – none

- Audio – requires device speaker or headphones

Accreditation

This course is ECITB approved. The Engineering Construction Industry Training Board (ECITB) is the skills, standards and qualifications body for the development of the engineering construction workforce of Great Britain. An arms-length body of the UK Government, the ECITB reports to the Department for Education. ecitb.org.uk

Recommended Courses

Reviews

Insights & News

At Mintra, we're so much more than just a team—we're a force driving innovation and excellence in maritime training across Europe.

We’re excited to be taking the stage at one of Europe’s leading showcases of organisational learning.

We are delighted to share the exciting news that our People and Culture team has been shortlisted for the prestigious cHeRries Awards!