Buy and assign to

multiple learners

Instant access

via email link

Instant certificate

via email

Further Information - Distillation Training

Description

Who is the course for?

This Distillation Training course is aimed at individuals working in the chemical industry who require an understanding of distillation processes. It is particularly suited to those who are new to the industry and do not have a background in chemistry.

Is previous experience required?

It is expected that as a participant in this course you will have received formal training in your designated role and that you hold suitable qualifications.

How will the course benefit me?

Distillation is a common process in the chemical industry where it is used to separate liquids into their component parts. This course will explain the principles of distillation and the operation of the equipment used in distillation systems.

The knowledge gained in this course will help you understand the safety hazards and precautions associated with distillation, and will enable you to work safely with distillation equipment.

How will the course benefit my company?

By ensuring that you are aware of the precautions to be applied when working with distillation equipment, you contribute to the safety of the asset, your fellow workers and yourself.

What standards are referenced in the course?

This course does not refer to specific legislation or laws but is written to current HSE guidelines, industry best practice and standard operating procedures.

Is there an assessment?

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

Learning Objectives

• Define distillation

• Explain the purpose of distillation in the chemical industry

• Describe the basic operation and construction of a distillation column

• Identify the basic terminology used in distillation theory

• Explain the basic terminology used in distillation theory

• Explain the effect of changes in temperature on the vapour pressure of a liquid

• Illustrate how to plot and interpret vapour pressure / temperature diagrams for pure liquids

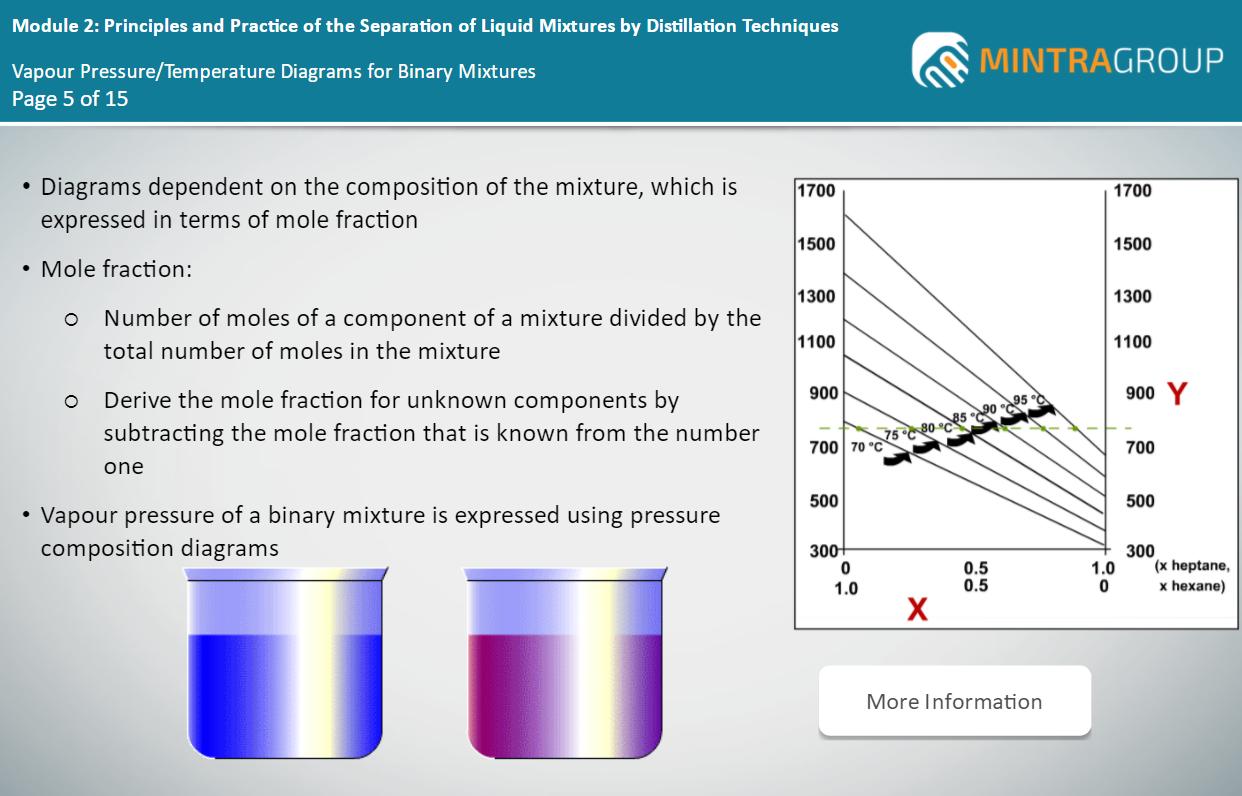

• Illustrate how to plot and interpret vapour pressure / temperature diagrams for binary mixtures

• Explain how vapour pressure relates to the boiling points of liquids

• Explain Dalton’s law of partial pressures

• Illustrate how Dalton’s law of partial pressures can be used in practical applications

• Explain Raoult’s law

• Illustrate how Raoult’s law can be used to calculate the total vapour pressure of ideal binary liquid mixtures

• Identify the differences between ideal and non-ideal liquid mixtures

• Explain the effects of boiling point differences on the separation of miscible liquids

• Illustrate how to construct and interpret vapour pressure / composition diagrams for binary mixtures

• Illustrate how to construct and interpret boiling point / compositional diagrams for binary mixtures

• Explain how to use point / compositional diagrams to estimate the number of theoretical stages for fractional distillation processes

• Identify the common distillation techniques

• Explain the principles behind each common distillation technique

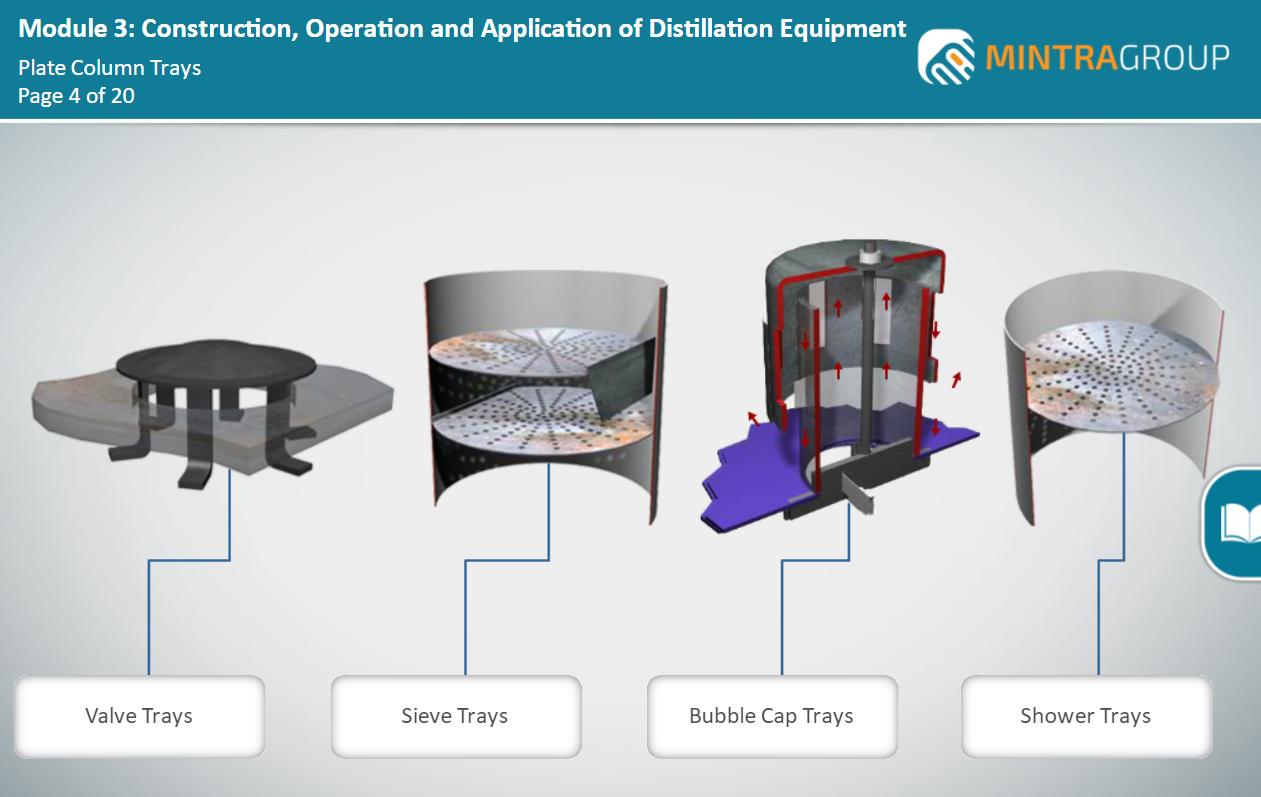

• Describe the construction, operation and application of plate columns

• Identify the different types of plate columns

• Describe the different types of plate columns

• Identify the three main components of plate columns

• Explain the function of the three main components of plate columns

• Explain the advantages and disadvantages of the different types of plates

• Describe the construction, operation and application of packed columns

• Identify the main types of column packing

• Describe the different types of column packing

• Compare and contrast packed and plate columns

• Identify the main operating problems associated with plate and packed columns

• Explain the main operating problems associated with plate and packed columns

• Identify the factors that affect the economics of column operation

• Explain the factors that affect the economics of column operation

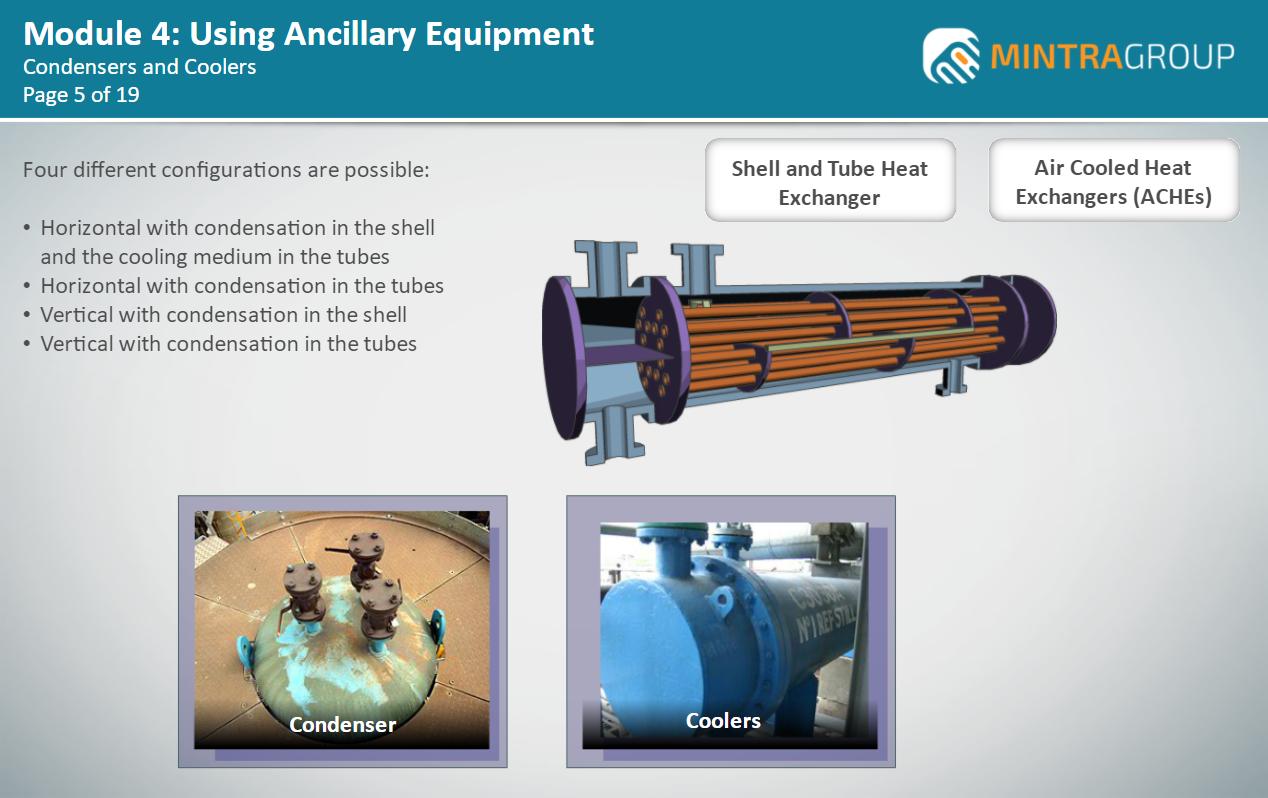

• Identify the different types of ancillary equipment

• Describe the construction, operation and application of the different types of ancillary equipment

• Identify the main process variables

• Explain how these process variables are controlled using ancillary equipment

• Identify the hazards associated with the distillation plant

• Describe the precautions required to minimise the different types of hazards

• Identify the different chemicals that are used to reduce operational hazards

• Identify the functions of the different chemicals that are used to reduce operational hazards

Assessment

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

System Requirements

• Internet access - users will need a device with a web browser and internet connection

• System - runs on computers, tablets and mobile devices using Windows 7 and above and MAC OS devices running IOS 11 and above

• Browsers - Edge, Chrome, Firefox and Safari

• Minimum browser size - none

• Audio - requires device speaker or headphones

Reviews

Insights & News

At Mintra, we're so much more than just a team—we're a force driving innovation and excellence in maritime training across Europe.

We’re excited to be taking the stage at one of Europe’s leading showcases of organisational learning.

We are delighted to share the exciting news that our People and Culture team has been shortlisted for the prestigious cHeRries Awards!