Buy and assign to

multiple learners

Instant access

via email link

Instant certificate

via email

Further Information - Safe Isolation & Reinstatement of Plant Training

Description

Who is this course for?

This Safe Isolation & Reinstatement of Plant Training Course is for personnel requiring awareness or understanding of SIRP.

Is previous experience required?

You do not need prior knowledge or experience to complete this course.

How will this course benefit me?

To ensure that relevant personnel have a common and consistent approach to industry best practice in relation to SIRP operations

How will this course benefit my company?

By ensuring you have an overview of industry best practice in relation to SIRP operations

What standards are referred to in this course?

This course does not refer to specific legislation or standards but is written according to industry best practice.

Is there an assessment?

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

Learning Objectives

• Explain the importance of safe isolations with respect to Integrity Management, particularly where activities could lead to potential major accident hazards or environmental spills

• Identify the hazards associated with breaking containment and the importance of human factors in preventing loss of containment

• Identify the key legislative requirements for isolation operations and the requirement to reduce risk to ALARP

• Describe the roles and responsibilities of key personnel involved in isolation and de-isolation operations

• Explain the considerations that must be taken when planning isolation work

• Identify the main methods of isolation and explain how to select the appropriate method of isolation

• Explain the requirements for carrying out a risk assessment for non-compliant isolations

• Describe the management of Long Term Isolations and redundant/mothballed equipment

• Explain how to ensure isolation security

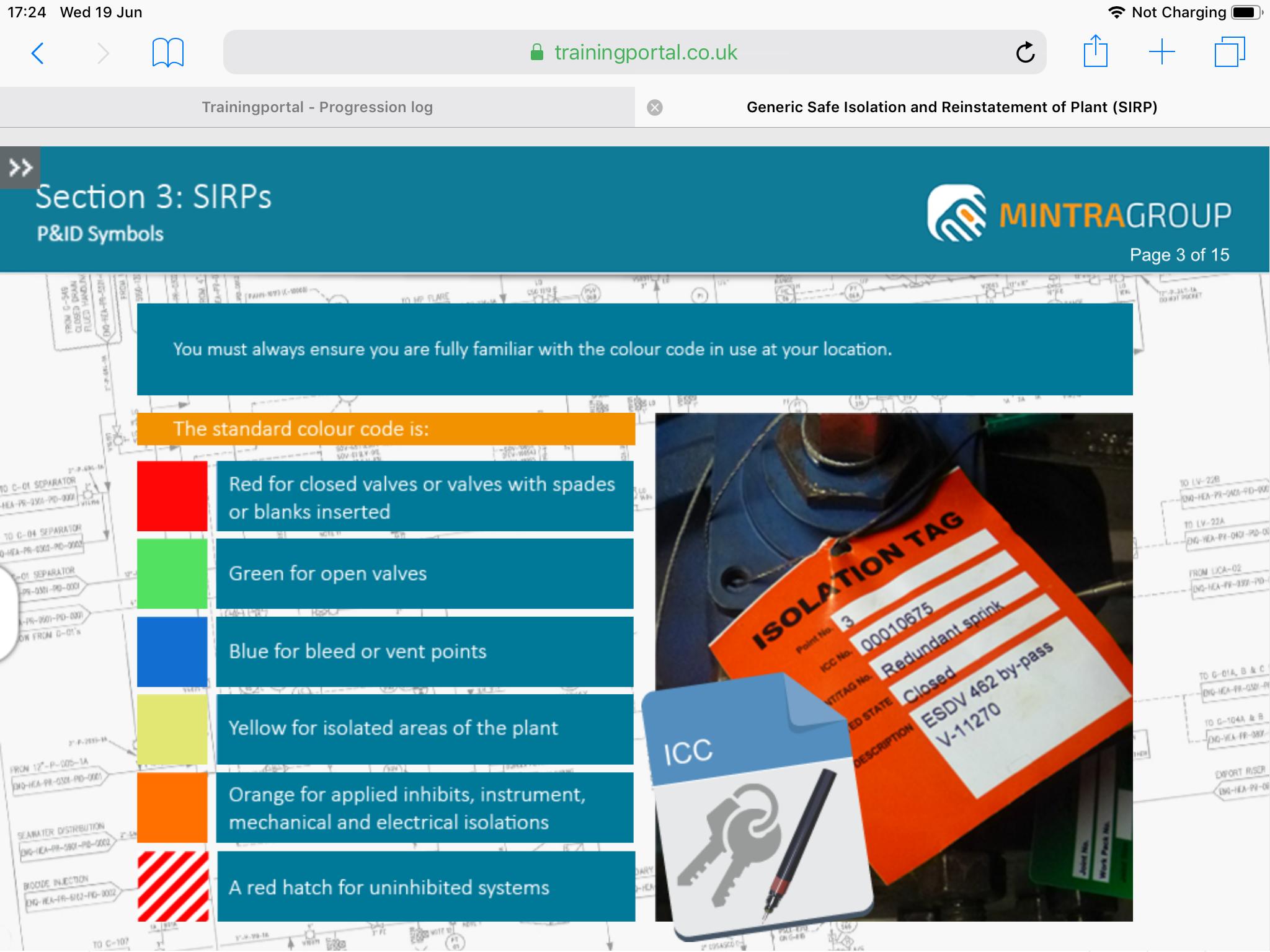

• Give an overview of the colours and symbols used for marking up isolations on P&IDs

• Give an overview of the flange testing and tagging process for positive isolations and breaking containment

• Explain the standards and process required for Personal Isolations

• Describe the requirements for Sanction to Test

• Give an example of how to test and monitor isolation integrity

• Identify the precautions to be taken when breaking containment

• Describe the requirements for draining and venting

• Give an overview of cleaning and gas-freeing methods

• Describe the importance of knowing the UELs and LELs of relevant gases

• Explain the requirements for the de-isolation of plant and equipment, including leak testing

• Explain how to select the correct leak test pressure, including pipework specification change identification and pressure relief requirements

• Give an overview of different types of leak tests and identify when they may be used

• Identify the steps required for the depressurising and return of plant to service

• Explain the process of carrying out post-test integrity checks

Assessment

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

System Requirements

• Internet access - users will need a device with a web browser and internet connection

• System - runs on computers, tablets and mobile devices using Windows 7 and above and MAC OS devices running IOS 11 and above

• Browsers - Edge, Chrome, Firefox and Safari

• Minimum browser size - none

• Audio - requires device speaker or headphones

Recommended Courses

Reviews

Insights & News

At Mintra, we're so much more than just a team—we're a force driving innovation and excellence in maritime training across Europe.

We’re excited to be taking the stage at one of Europe’s leading showcases of organisational learning.

We are delighted to share the exciting news that our People and Culture team has been shortlisted for the prestigious cHeRries Awards!