Buy and assign to

multiple learners

Instant access

via email link

Instant certificate

via email

Further Information - Mechanical Joint Integrity Training

Description

Who is this course for?

This Mechanical Joint Integrity Training course is aimed at all personnel involved in mechanical joint operations, particularly those who are expected to undertake related duties in the workplace.

Is previous experience required?

You do not need prior knowledge or experience to complete this course and it is assumed that you are competent in your designated role

How will this course benefit me?

This course aims to provide learners with an introduction to the principles of the equipment and technology associated with the bolting of flanged joints for pressurised systems. This course is intended to reflect industry """"best practice"""" for competence in relation to mechanical joint operations and applies to both the onshore and offshore Oil and Gas Industry.

This course contains the following sections:

Section 1: An Introduction to Mechanical Joint Integrity

Section 2: Principles of Hand Torquing

Section 3: Principles of Hydraulic Tensioning

Section 4: Principles of Controlling Tightening

How will this course benefit my company?

By ensuring you are introduced to the principles of the equipment and technology associated with the bolting of flanged joints for pressurised systems

What standards are referred to in this course?

N/A

Is there an assessment?

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

Learning Objectives

Section 1: An Introduction to Mechanical Joint Integrity

• Explain the importance of ensuring mechanical joint integrity

• Describe what is meant by ‘a mechanical joint’

• Identify different types of flanges and flange connections

• Describe how to install flanges correctly

• Describe the principles behind the use of nuts and bolts

• Explain the physical properties of bolts

• Explain how to choose the correct nut type

• Identify different types of gaskets

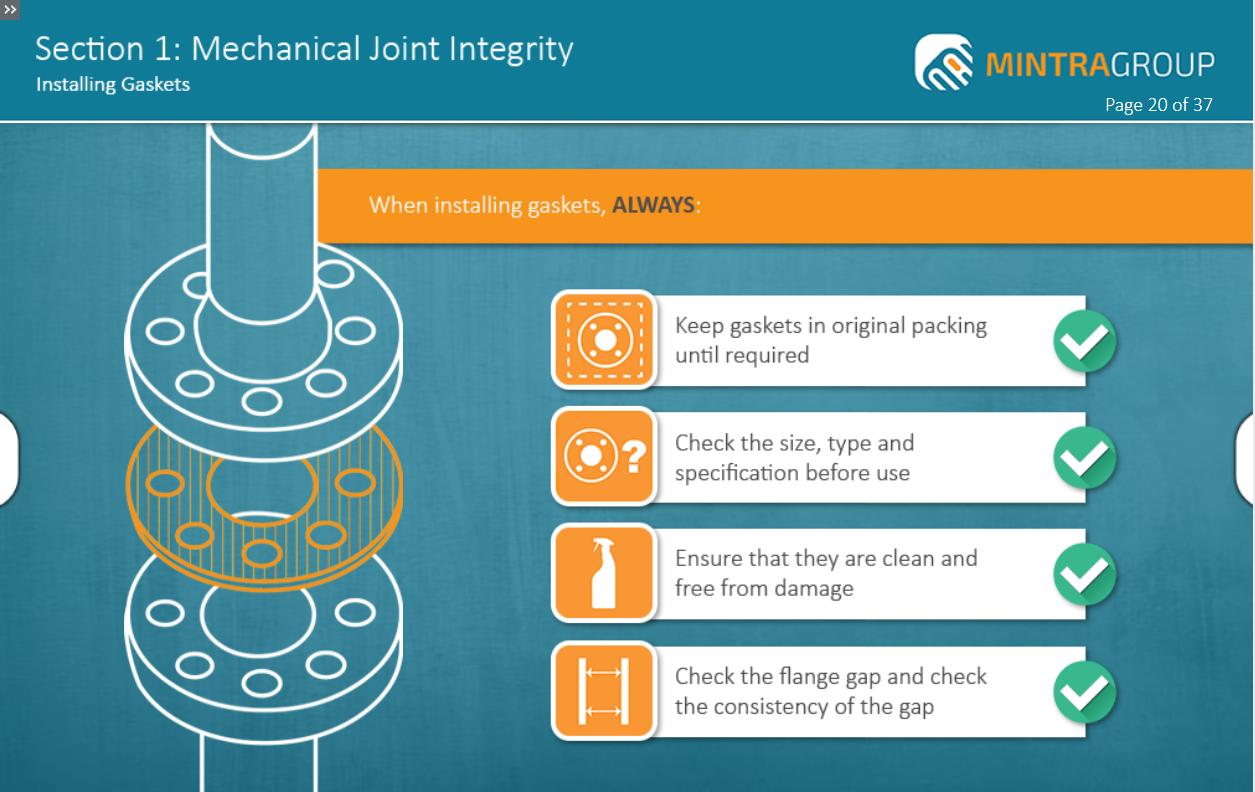

• Explain what should be checked when installing gaskets

Section 2: Principles of Hand Torquing

• Identify what is meant by ‘torque’

• Explain how to reduce friction and the importance of lubrication

• Explain the importance of tightening and identify correct tightening methods

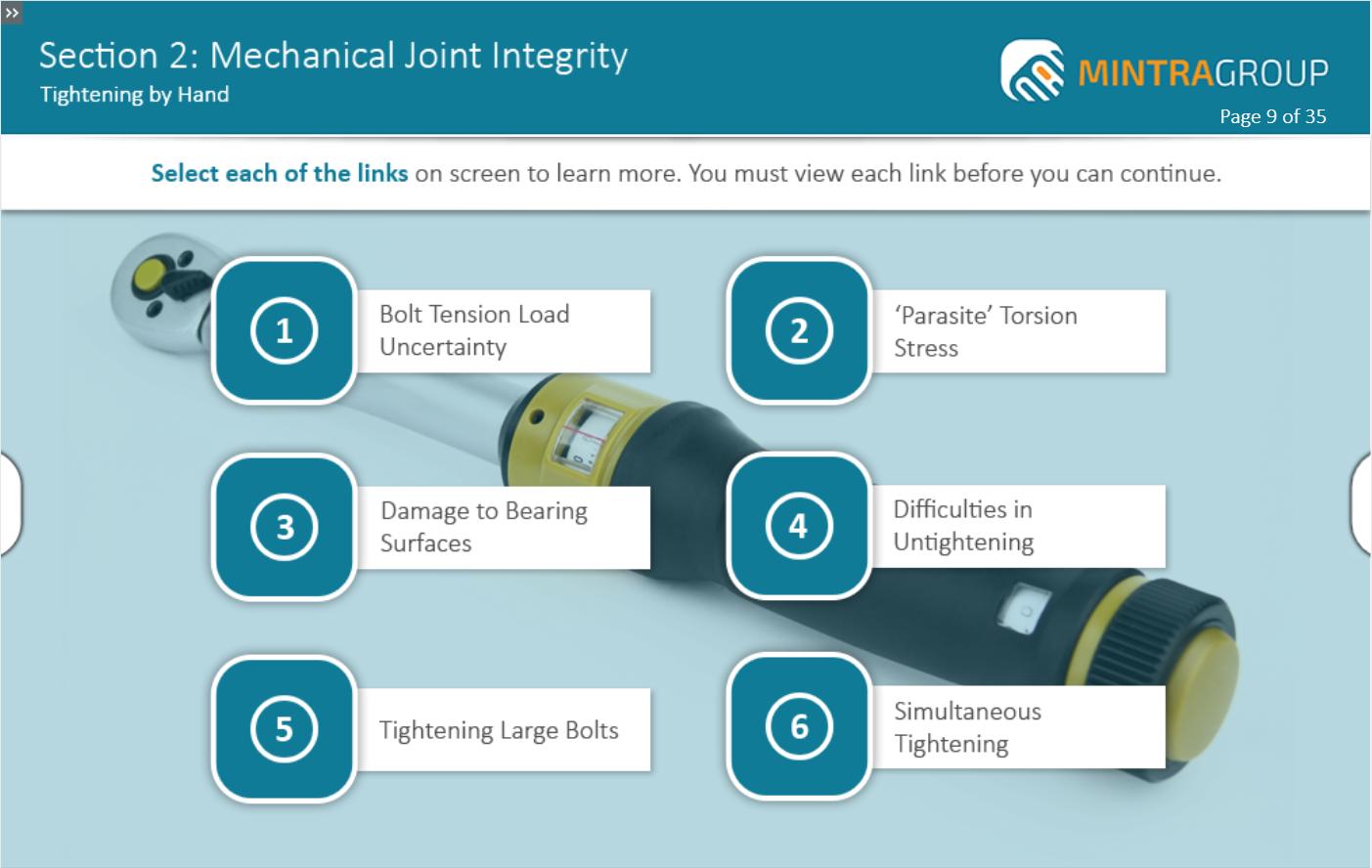

• Describe the disadvantages of using hand torquing methods

• Identify different methods of measuring torque tightening

• Give examples of risks associated with hand torquing methods

Section 3: Principles of Tensioning

• Identify different tensioning techniques

• Explain how to use heater rods

• Explain how to use hydraulic bolt tensioners

• Explain the principles behind mechanical elongation

• Identify the main limitations of hydraulic wrenches

• Describe correct tightening methods

• Identify the advantages of hydraulic tightening

• Identify different methods of measuring tensioning

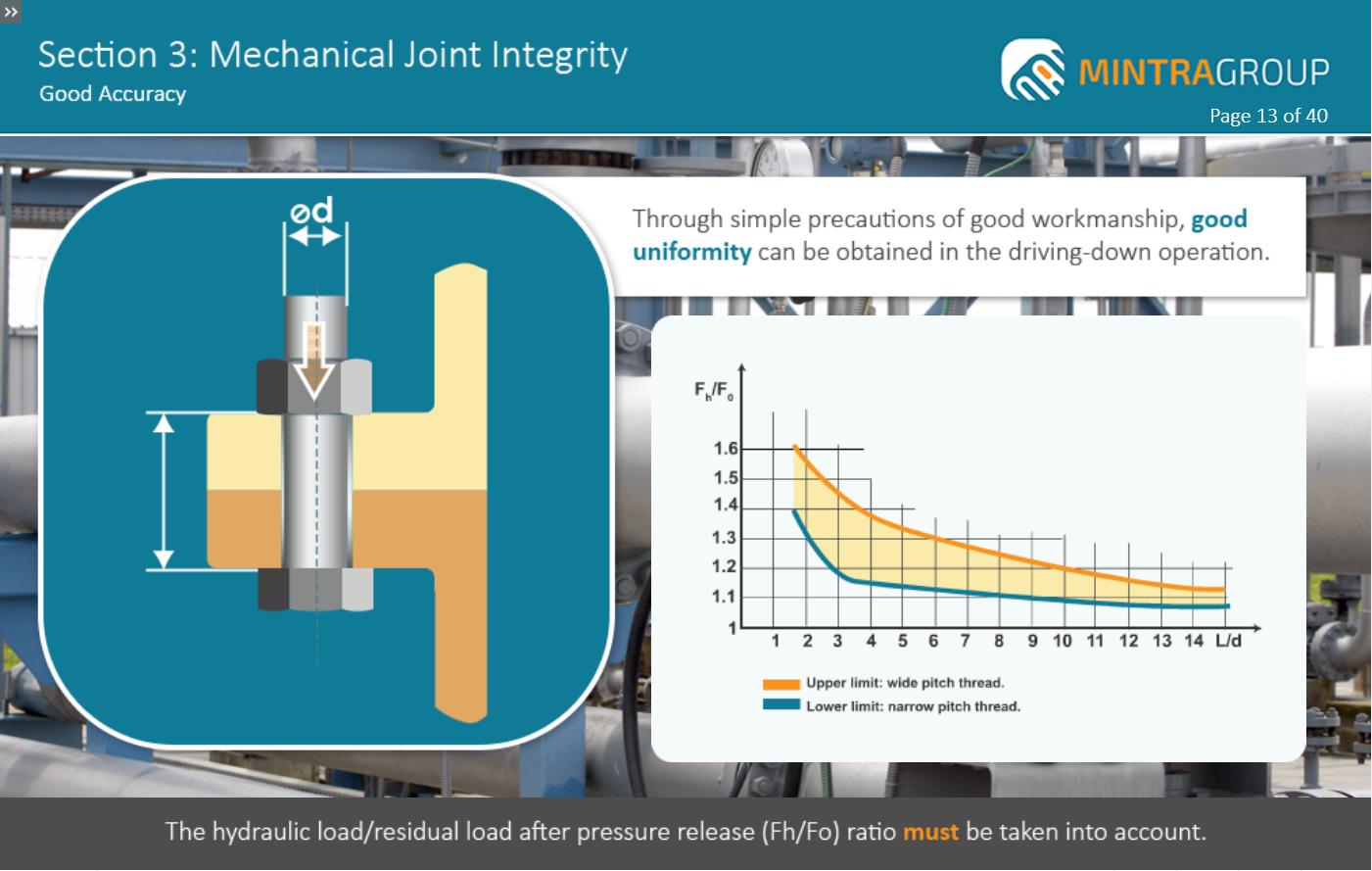

• Explain the relationship between hydraulic tensioning and tension stress

Section 4: Principles of Controlling Tightening

• Identify the three main methods of tightening

• Describe what is meant by ‘uncontrolled’ tightening

• Describe what is meant by ‘partially controlled’ tightening

• Describe what is meant by ‘fully controlled’ tightening

• Identify the different measuring tools available for carrying out fully controlled tightening

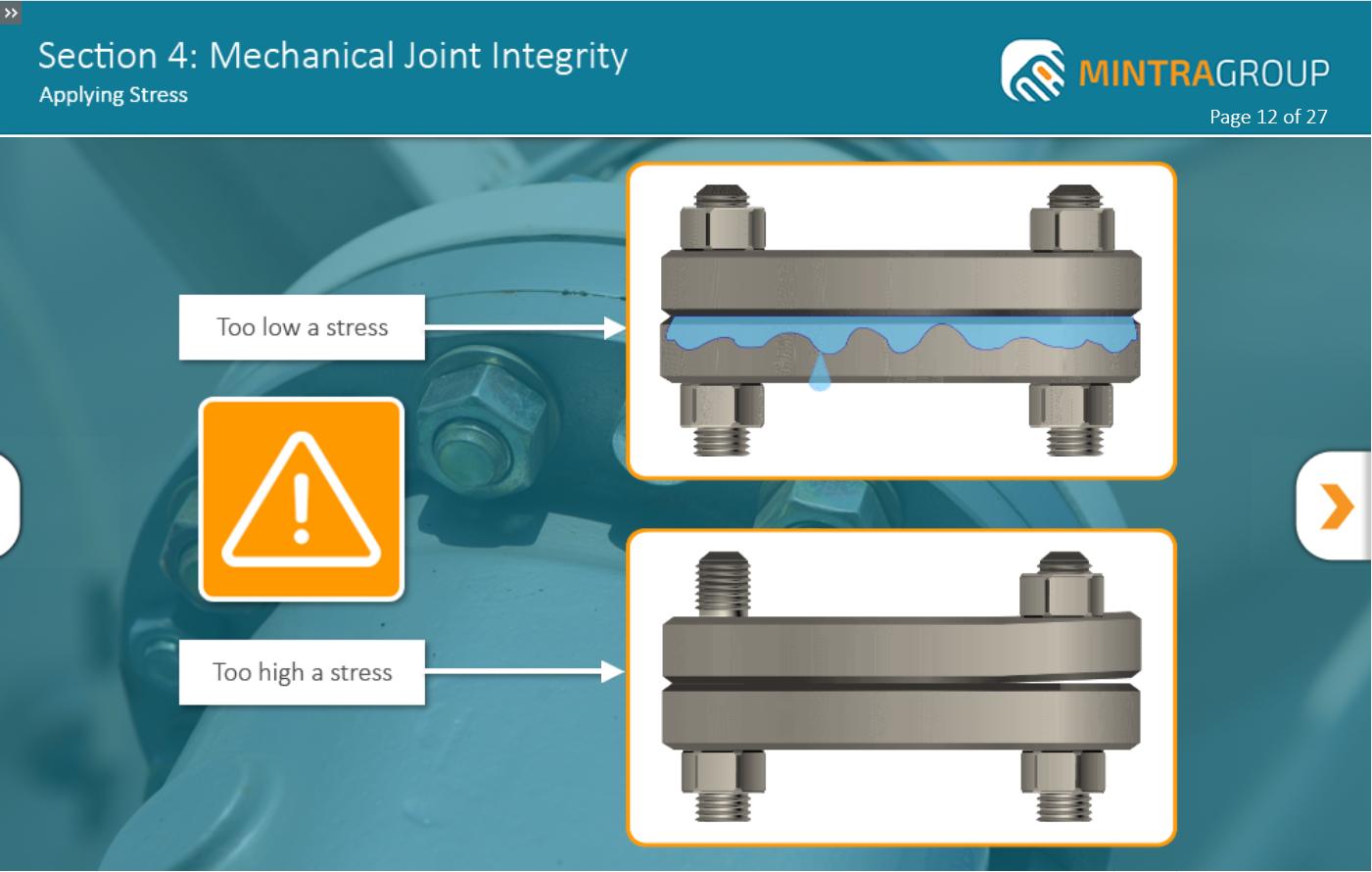

• Explain the importance of applying the correct amount of stress

• Describe the effects of using too low a stress

• Describe the effects of using too high a stress

• Give an overview of best mechanical joint integrity practice

Assessment

Exam in the e-learning course

System Requirements

• Internet access - users will need a device with a web browser and internet connection

• System - runs on computers, tablets and mobile devices using Windows 7 and above and MAC OS devices running IOS 11 and above

• Browsers - Edge, Chrome, Firefox and Safari

• Minimum browser size – none

• Audio – requires device speaker or headphones

Reviews

Insights & News

At Mintra, we're so much more than just a team—we're a force driving innovation and excellence in maritime training across Europe.

We’re excited to be taking the stage at one of Europe’s leading showcases of organisational learning.

We are delighted to share the exciting news that our People and Culture team has been shortlisted for the prestigious cHeRries Awards!