Buy and assign to

multiple learners

Instant access

via email link

Instant certificate

via email

Further Information - Process Safety Training

Description

Who is this course for?

This Process Safety Training Course is for personnel such as processors or trainee processors requiring awareness or understanding of the various process safety systems.

Is previous experience required?

You do not need prior knowledge or experience to complete this course.

How will this course benefit me?

This course aims to provide learners with an overview of the various process safety systems that are employed in the Oil and Gas Industry.

How will this course benefit my company?

By ensuring you have an overview of the process of the various process safety systems that are employed in the Oil and Gas Industry.

What standards are referred to in this course?

This course does not refer to specific legislation or standards but is written according to industry best practice.

Is there an assessment?

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

Learning Objectives

Section 1: Hazards of Hydrocarbons

- Provide an example of a major fire and explosion

- Describe the explosive envelope

- Describe how fire and explosions occur

- Describe the effects of loss of containment

- Identify the possible causes of loss of containment

- Summarise the hazards of hydrocarbons

Section 2: The HAZOP Process

- Describe the need for HAZOP studies

- Identify what can go wrong when a HAZOP study is not carried out

- Describe the history of the HAZOP process

- Describe the HAZOP process

- Describe how the HAZOP study is recorded

- Describe what may go wrong if deviations are not identified

- Describe the HAZOP terms of reference

- Describe the HAZOP team

- Describe HAZOP scheduling

- Summarise the HAZOP process

Section 3: Safety Instrumented Systems

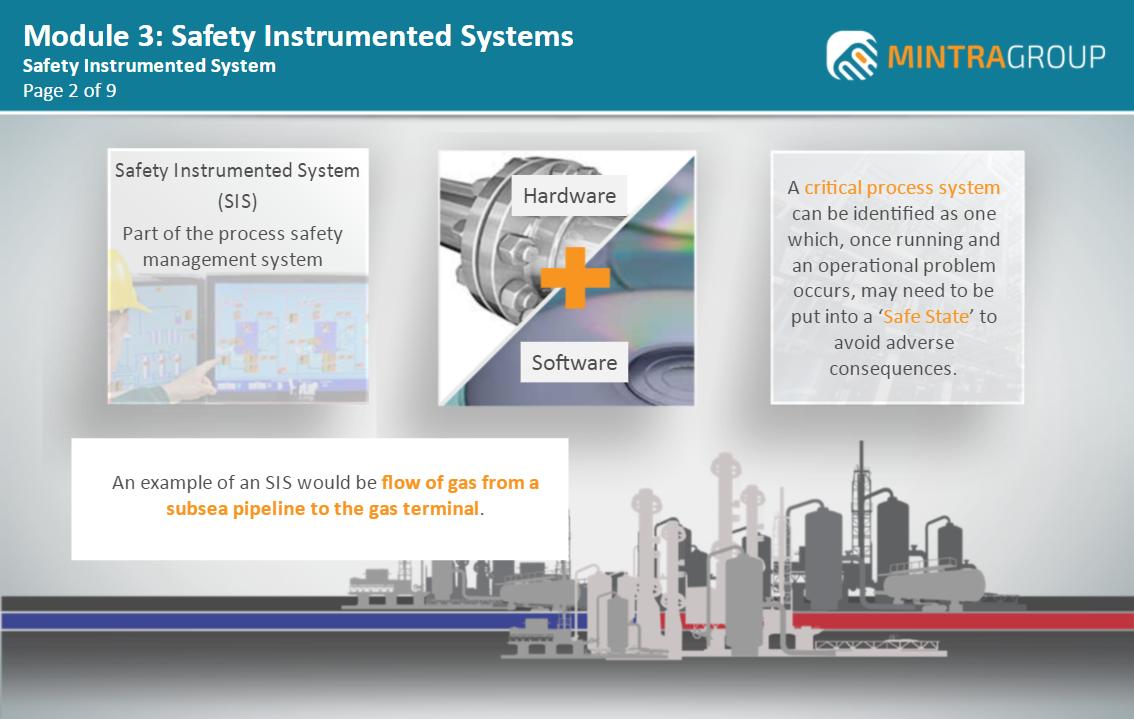

- Describe a Safety Instrumented System (SIS)

- Describe how to select an SIS

- Describe the SIS process

- Identify the layers of protection

- Describe Failure on Demand

- Describe the Safety Integrity Level

- Summarise the SIS

Section 4: Fire and Gas Systems

- Describe the purpose of fire and gas systems

- Describe how Ultraviolet flame detectors work

- Describe how Infra-Red flame detectors work

- Describe how UV/IR flame detectors

- Describe how heat detectors work

- Describe how smoke detectors work

- Describe how ionisation detectors work

- Describe how optical detectors work

- Describe how High Sensitivity Smoke Detection (HSSD) works

- Describe the use of gas detectors

- Describe how catalytic gas detectors work

- Describe how Infra-Red gas detectors work

- Describe how Open Path gas detectors work

- Summarise Fire and Gas systems

Section 5: Overpressure Protection

- Describe the intent of overpressure protection systems

- Identify methods of overpressure protection

- Identify additional overpressure protection devices

- Describe active and passive overpressure protection devices

- Identify a case study involving overpressure

- Describe relief valves and their function

- Describe bursting discs and their function

- Describe High Integrity Pressure Protection Systems (HIPPS)

- Summarise overpressure protection systems

Section 6: Managing Pressure and Leak Testing

- Describe pressure testing

- Describe the role of the Leak Tester

- Identify risk reduction methods

- Describe leak testing

- Identify examples of the various mediums for pressure and leak testing

- Describe the use of helium trace gas

- Describe the HeliTest unit

- Identify risk reduction methods

- Summarise pressure and leak testing

Section 7: Management of Change

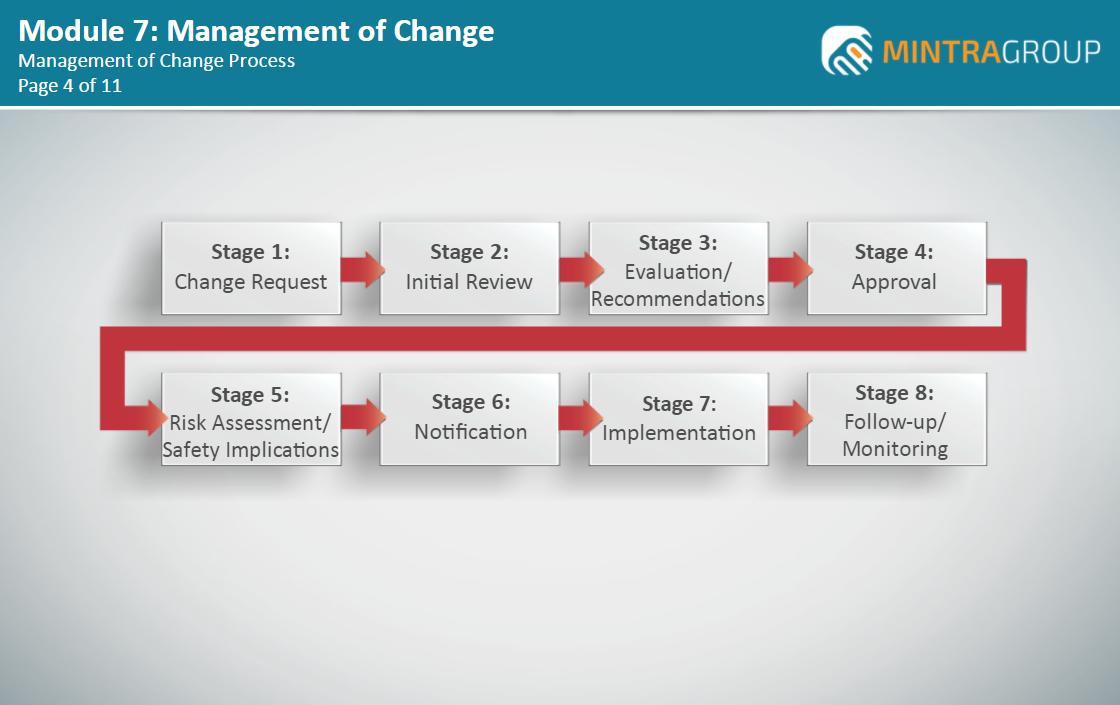

- Describe management of change

- Describe the management of change process

- Summarise Process Safety

Assessment

Once you have completed the course, you will be asked a series of questions to check your knowledge and understanding. These are based on the learning objectives for the course and have a pass mark of 80%.

System Requirements

• Internet access - users will need a device with a web browser and internet connection

• System - runs on computers, tablets and mobile devices using Windows 7 and above and MAC OS devices running IOS 11 and above

• Browsers - Edge, Chrome, Firefox and Safari

• Minimum browser size - none

• Audio - requires device speaker or headphones

Recommended Courses

Reviews

Insights & News

At Mintra, we're so much more than just a team—we're a force driving innovation and excellence in maritime training across Europe.

We’re excited to be taking the stage at one of Europe’s leading showcases of organisational learning.

We are delighted to share the exciting news that our People and Culture team has been shortlisted for the prestigious cHeRries Awards!